We convey joy by bringing the comfort of footwear to the world, in step with changing needs, while respecting our planet.

“The female universe. Pure energy, innate elegance, overwhelming harmony, a personality that seduces and conquers. This wonderful mystery inspires and shapes my shoes, as the personal expression of the essence of every woman.”

We convey joy by bringing the comfort of footwear to the world, in step with changing needs, while respecting our planet.

We are a

MULTIPROCESS

Company

…versatile, independent and internationally competitive.

We produce various product lines quickly and efficiently:

- assembled articles

- Strobel stitching

- hand-sewn items

- direct injection

- full injection

- EVA injection

- knit uppers

We use different technologies and materials, adapting to specific needs and various markets.

We manage all production phases: design, research, prototyping, production and packaging

“The female universe. Pure energy, innate elegance, overwhelming harmony, a personality that seduces and conquers. This wonderful mystery inspires and shapes my shoes, as the personal expression of the essence of every woman.”

OUR FACTORIES

We manage the entire development cycle of each project, from defining the style to technical aspects, from prototyping to final production.

Our main production site is located in Bosnia, in a 30,000 m² state-of-the-art factory with over 700 employees. To support production, we also work with external partners in Bosnia, Albania and Tunisia, with an additional 600 employees.

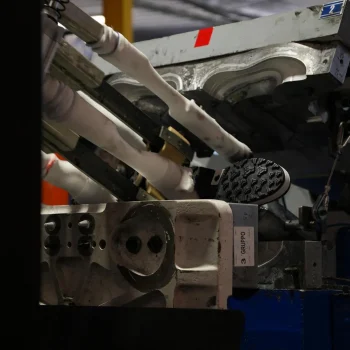

Between Italy and Bosnia, our machinery consists of 18 rotary machines, 5 EVA injection machines, 3 static machines and 3 direct-injection machines. This allows us to achieve a daily production capacity of around 35,000 pairs of injection-moulded shoes and 3,000 pairs of assembled articles.

We manage the entire development cycle of each project, from defining the style to technical aspects, from prototyping to final production.

We specialise in the production of casual shoes, sport shoes and comfort footwear.

Each item is followed through all production stages with the utmost care, right up to rigorous quality control, including leak tests conducted using specialised machinery.

Research and Development

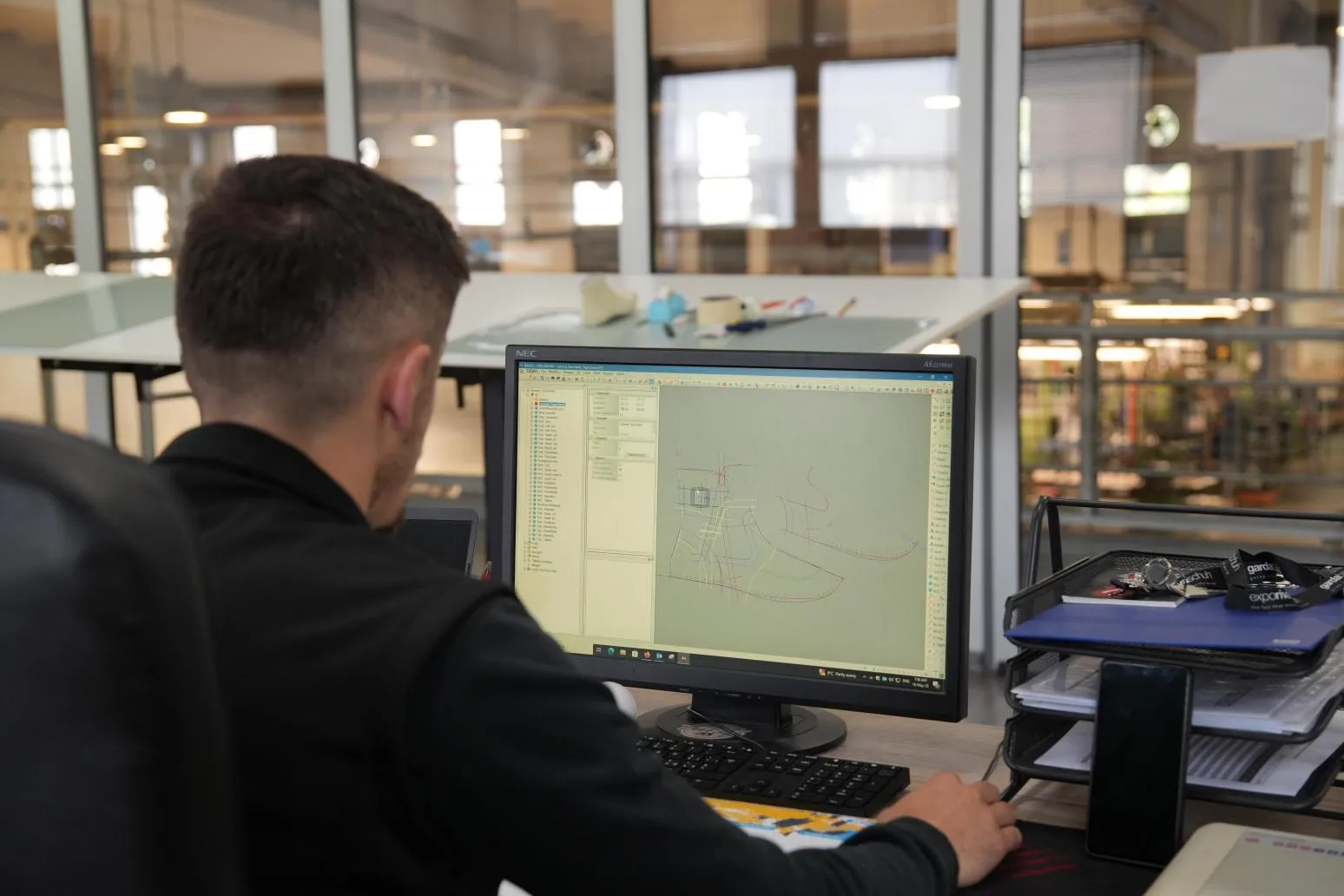

The innovative heart of our company moves between Italy and Bosnia, where the R&D department works every day to transform ideas into outstanding products.

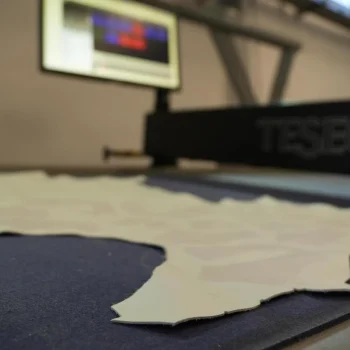

The team consists of eight experienced pattern makers, supported by specialists in the joining department who follow every stage of the project, from the initial concept to the design, through to final development.

We use state-of-the-art software such as Adobe Photoshop and Illustrator for creative design, and technical programmes such as iCad 3D and Naxos for development and modelling.

This combination of manual skills and digital tools allows us to tackle all sorts of design challenges with precision and a clear vision.

We constantly invest in research and development, with respect to both technology — with the introduction of new machinery, innovative components and advanced solutions — and creativity, guaranteeing collections that are always up-to-date and in line with market developments

Why MULTIPROCESS?

…versatile, independent and internationally competitive.

We produce various product lines quickly and efficiently:

- assembled articles

- Strobel stitching

- hand-sewn items

- direct injection

- full injection

- EVA injection

- knit uppers

We use different technologies and materials, adapting to specific needs and various markets.

We manage all production phases: design, research, prototyping, production and packaging

MARKETING AND COMMUNICATION

To enhance each collection and increase brand awareness, we adopt an integrated marketing strategy that includes professional photo shoots, catalogues for end customers and retailers, customised information materials and active participation in trade fairs.

We invest in traditional and digital advertising with print campaigns, Google Ads and a strategic presence on social media.

Online visibility is enhanced by an up-to-date website, intuitive online shop and regularly published content. Each action is designed to support sales and build a solid connection with the public.